Electromagnetic Cloak

SensorMetrix has pioneered and specialized in the development of EM cloaking structures, which includes design, simulation, prototype, and characterization of cloaks for various defense and commercial applications. We have performed the first experimental demonstration of a cloak made of metamaterials in 2006, the results of which appeared in Science magazine. Since then, SensorMetrix has led and participated in several R&D effort to develop innovative cloaking technology, most of which are funded by DoD agencies. The resulting technology advancement enables novel solutions to many demanding RF and microwave devices and systems, such as antenna, radar, electromagnetic interference, and low observable materials.

|

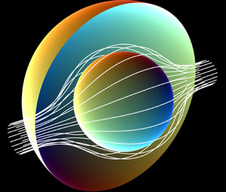

Over the past decade, metamaterials have seen steadily increasing interest from the defense community as potential solutions to complex electromagnetic problems. Extending from metamaterial concepts, the design methodology of Transformation Optics provides a way to direct EM waves to follow a specified trajectory through a region of space using material properties (specifically the electric permittivity and magnetic permeability). In this methodology, it is imagined that free space is distorted in such a way as to send optical rays along new desired paths. Shown in figure 1 is a simple transformation that bends all rays around a central volume. It illustrates how parallel rays propagate in free space in the original coordinate system, are then transformed into smoothly curved rays inside the shell region of the cloak, and ultimately exit the cloaking region with the same orientation as when incident. In this way, the fields reemerged from the cloaked region as if they had passed through free space, unscattered.

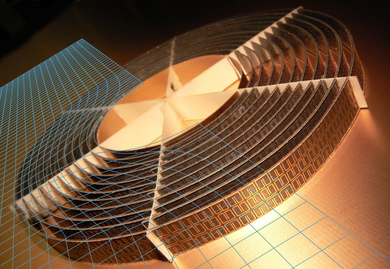

A mathematical description, in the form of a space transformation, is developed that describes the imagined distortion. It exploits the property that Maxwell’s equations are invariant under coordinate transformations and interprets spatial transformations using distributions of inhomogeneous and anisotropic constituent materials. At SensorMetrix, the validity of cloak designs is supported by full-wave electromagnetic simulations. For instance, the performance of a cylindrical cloak design is illustrated in figure 2, where no scattering can be observed and the fields outside the cloak are exactly the same as if the cloak and the cylinder were not present in the first place.

The first cylindrical cloaking structure was constructed at research group of Prof. David Smith, a SensorMetrix founder, by using metamaterials. These artificially structured materials provide uniquely engineered electromagnetic material properties, which are used to control the propagation of electromagnetic waves in a way that nature would not otherwise permit. In this case, the cloaking device was achieved by varying the dimensions of a series of split-ring resonators to yield the desired gradient of permeability in the radial direction. |

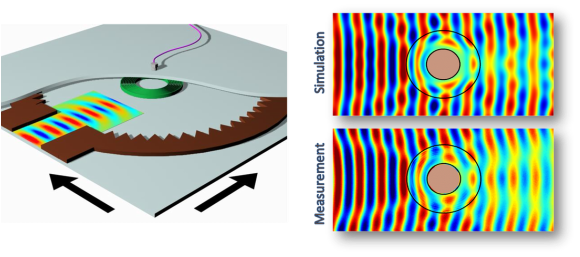

The first experimental demonstration of cloak was completed at SensorMetrix, in which the team employed a parallel plate waveguide system to map the EM wave propagation through the cloak. The results of the experiments are summarized in figure 4.

The novel cloaking concepts and corresponding capabilities are introduced at the research level. SensorMetrix has been working to complete the transition of these technical advances into real world applications. In particular, SensorMetrix has developed advanced simulation and optimization capabilities in order to implement arbitrarily complex material properties. Furthermore, the team has developed and demonstrated precise, large-scale fabrication and assembly methods on materials that provide advanced electromagnetic functionalities with low losses. As a result, three-dimensional, large scale cloaking structures with desired tolerance and manufacturability become available as advanced EM solutions.